Smart Prodcuts

kilews

The KL-GTCS Controllerallows you to be in full control of your entire fastening process.

Easily setup multiple tightening parameters like speed, time, thread, direction,

torque and angle directly on the user-friendly touch screen HMI. Create multiple jobs for different assembly stages and quickly switch between desired job dynamically.

Tightening data can be transferred out using the built-in Ethernet Module via Modbus TCP protocol.

Features

- High precision torque transducer

- High resolution angle encoder (1° - 30600°)

- Internal device storage 1 GB (Save up to 1,000,000 tightening data files)

- Program up to 8 unique rundown steps per sequence

- Program up to 99 sequences per job in normal mode and 50 sequences per job in advanced mode

- Save up to 99 jobs in normal mode and 70 jobs in advanced mode

- Export tightening data and job profiles via USB memory stick or FTP

- Customizable I/O for PLC integration

- Modbus TCP Communication Protocol

Features

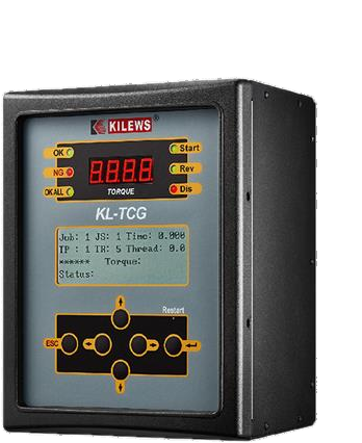

- digits and 7 Segment of torque display

- 24x4 LCM display settings

- Password and key control to avoid operator adjusting settings

- Counting preference set up (count up and count down)

- Slow start time 0.0~9.9 sec

- Slow start speed (10%~90%,L1 ~ L9)

- Work piece in place sensor (on/off)

- Set up fastening thread range

- I/O signal (Opt coupler)

- RS-232 interface for data output, storage and use with barcode scanner

- 99 data storage

- Set up fastening time range

- Set up fastening torque range

- Error code

- Auto learning

- Change torque unit

- Offset setting

- External start

- External reverse

- External disable tool

- External confirm

- Slot for SD memory card

- Built-in power

- Ethernet

.png?width=3114&height=1647&name=Huggen_Logo_25%20(1).png)